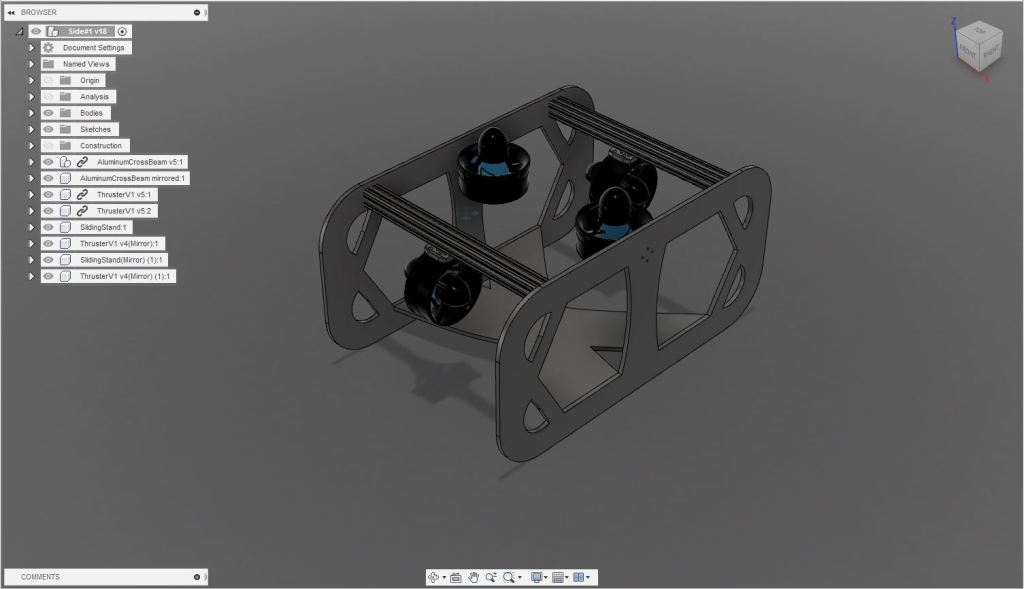

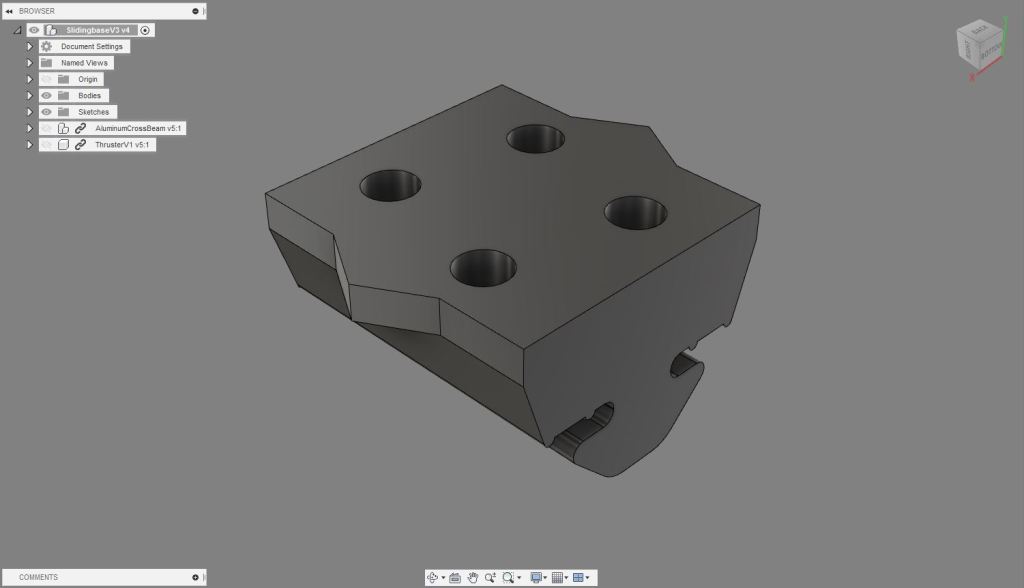

It’s been a couple of weeks since the last time I worked in the shop of the school. From the comfortable seat of my house I have been learning CAD, and also have been taking coding classes.

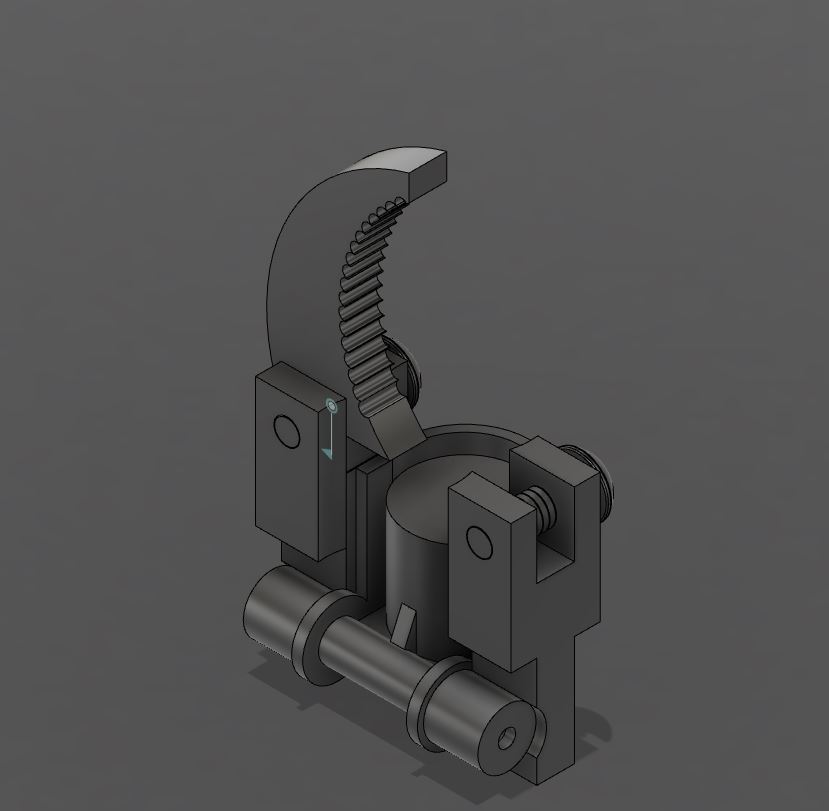

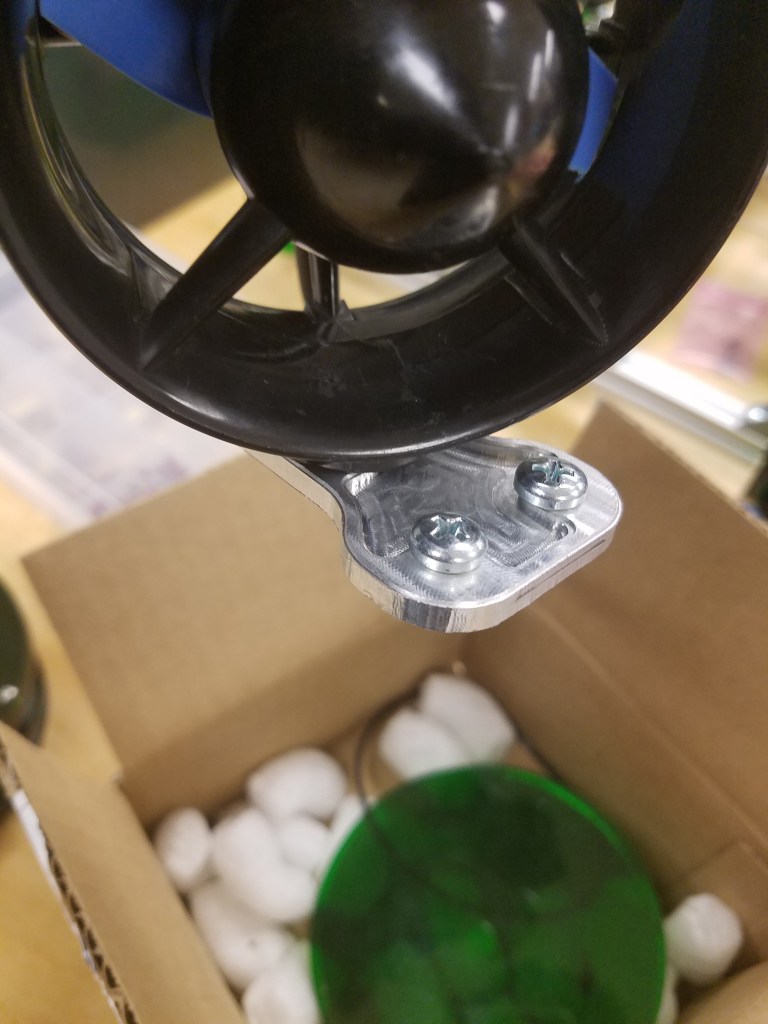

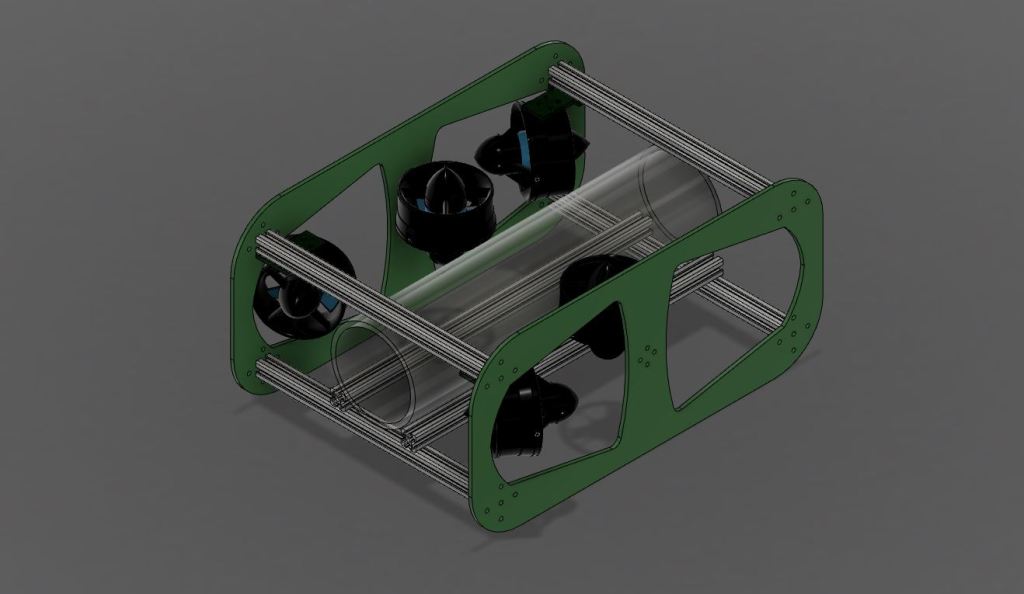

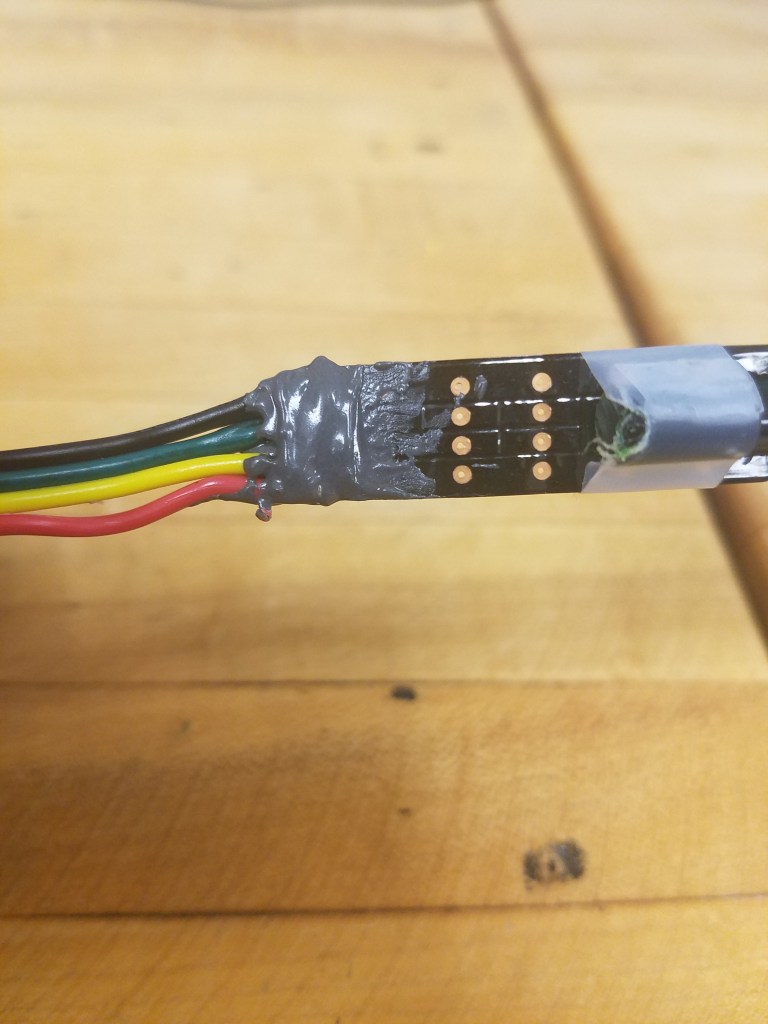

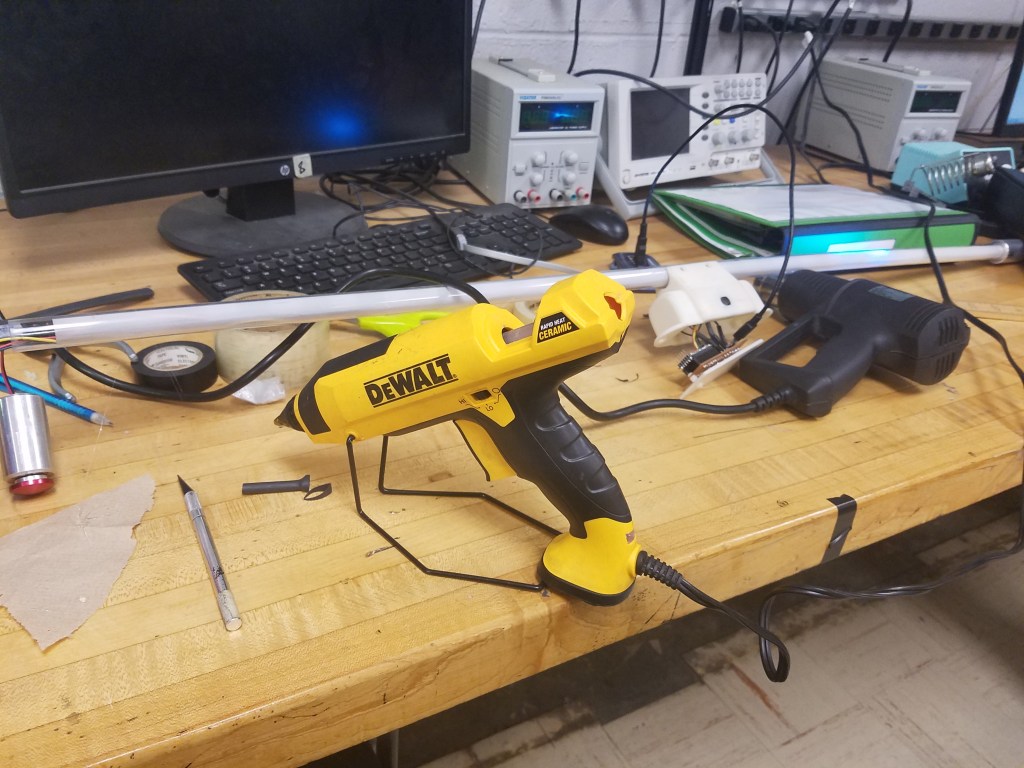

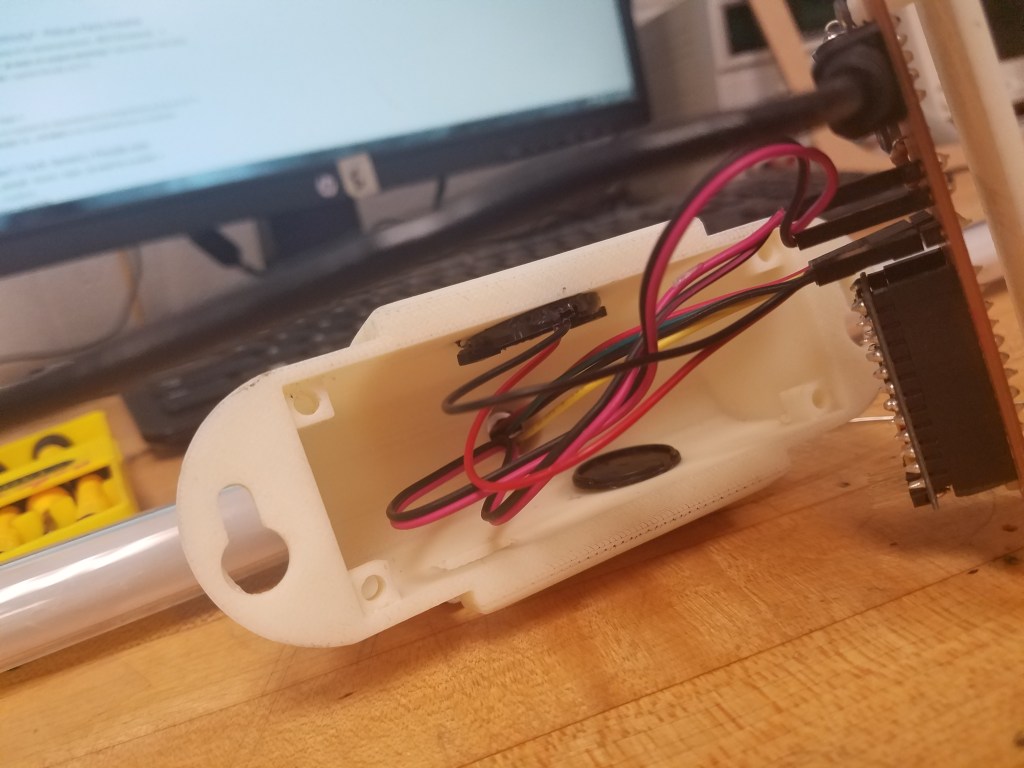

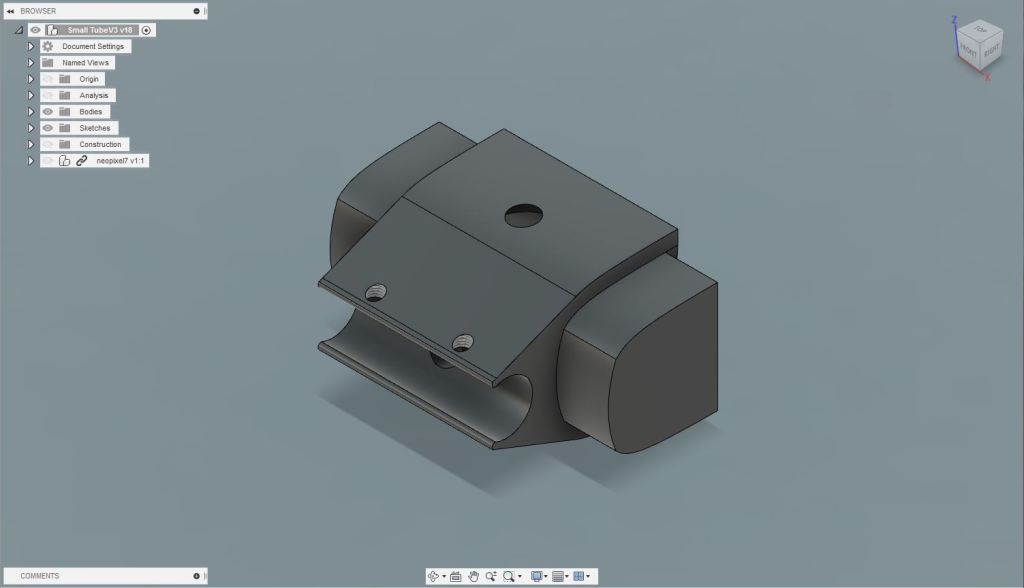

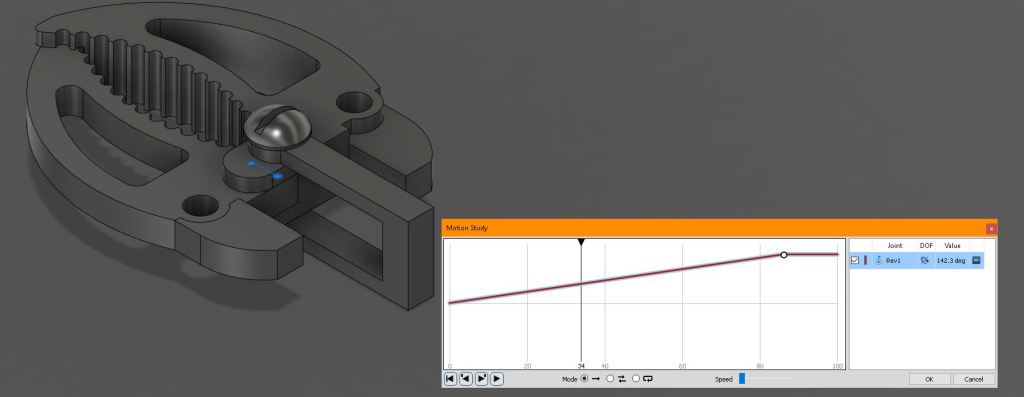

Even thought the design isn’t fully functional yet, the gripper is is getting shaped by the time, and so is the piston that is going to be attached to it eventually.

This is the first time I work with JavaScript, the first challenge was to work on a square shape that moves, and so does mine! It is not the most complex code, but it gets the job done. https://www.openprocessing.org/sketch/867855